As we enter a new year, there is an acceleration of automation, increased use of finishing, and continued growth in the purchase of printed materials from web-to-print sites. It is also safe to say that the tidal wave of change from analogue to digital is being amplified by the current unprecedented situation. Konica Minolta reveals the six trends in commercial printing in 2022.

Printing as an essential part of multi-channel communication

The demand for complete manufacturing processes, including more and more all-in-one solutions, and the need for production equipment that requires little operator intervention continue to grow.

Commercial printing technologies continue to expand beyond graphic and packaging applications. They are increasingly used in areas such as wallpaper, decoration and general industry. Inkjet technology for textiles, ceramic printing, printed circuit boards or glass is a new horizon that visionaries in the printing world are exploring.

Helping brands meet the changing demands of their customers for commercial printing

Brands are increasingly turning to digital to drive engagement and interest in their products, all in the context of a more sustainable environment. Responding quickly with highly automated systems that produce small quantities is one way to succeed. It also helps brands meet the ever-changing demands of their own customers. Simplifying production so that customer expectations can be met quickly is paramount. Software tools and equipment automation are also a significant source of profitability. Software features offer the possibility to automate workflows, customise the print and handle finishing efficiently.

A range of new possibilities with exciting label and packaging solutions

Brands are looking for innovative and attractive printed materials for commercial and industrial applications. They want to be supported in rethinking their printing possibilities.

The growth of e-commerce is certainly a factor in the growth of digital label and packaging production. This change in behaviour will have significant implications for commercial printers who will need to be able to react quickly. They will, for example, need to be able to develop products suitable for e-commerce to complement those for in-store sales. The production of different versions and customisation is also increasing.

Digital technology continues to gain ground

Digital printing has become the technology of choice for a wide range of applications and markets. As traditional print volumes continue to erode, printers are expanding their digital print service offerings.

According to the Smithers report "Future of Print to 2030", "the shift from analogue to digital continues, with the Covid-19 pandemic accelerating the transition driven by the growing importance of time-to-market and responsiveness."[1]

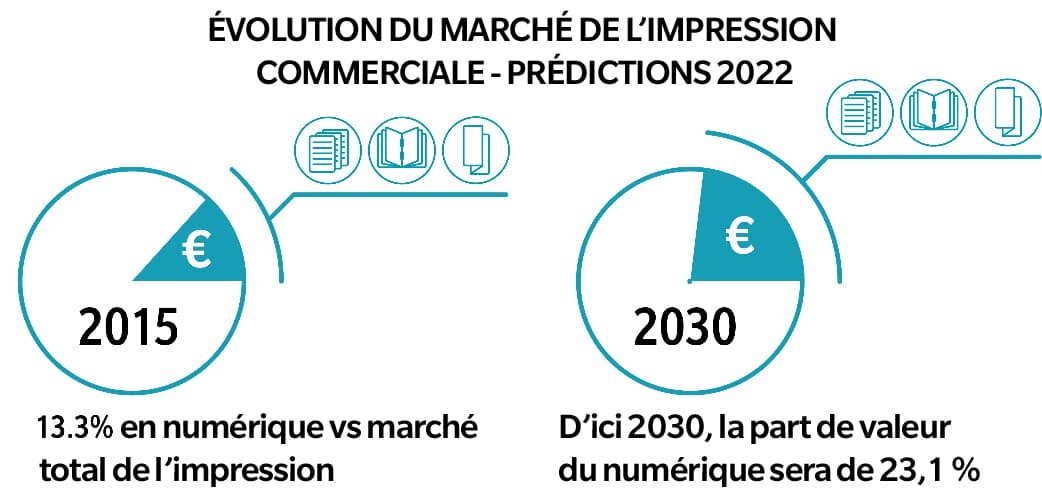

« In 2015, digital accounted for 13.3% of the global print market and 2.3% of print volumes, the bulk of which was graphic applications, books and labels. By 2030, the packaging sector will grow significantly, with digital accounting for 23.1% of the market and 6.3% of print volumes. Companies that embrace this technology will be ahead of the curve. ».

Digital printing is expanding into the majority of profitable printing applications and into the label and packaging sectors. The report [2] highlights that toner and inkjet technologies are available in a variety of forms, with monthly production capacity ranging from the equivalent of a few hundred A4 pages per month to hundreds of millions.

Meeting the demands of the changing commercial printing market

With a market share of 22.2% in 2020, Konica Minolta ranks second in Western Europe in the digital sheet-fed press segment. This ranking is partly due to its top-of-the-line AccurioPress C14000 product, which prints at 140 A4 pages per minute.

« Konica Minolta continues to manufacture products to meet the demands of the changing print market," the report said."

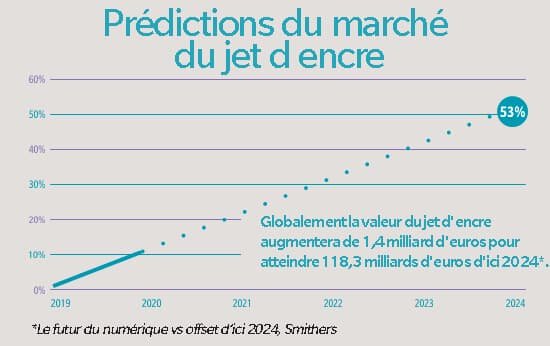

According to Smithers, the value of inkjet printing will grow globally by $41 billion to $118.3 billion (53%) over five years by 2024.

Konica Minolta is a major player in this technology, and the market potential of inkjet is the reason for the launch of the B2+ digital colour sheetfed press, AccurioJet KM-1e. It is a bridge between offset and digital printing.

Digital finishing: a key growth driver

Digital finishing also continues to be one of the key growth drivers in the production printing market. It is also the way in which print service providers, commercial printers and in-house corporate print departments can differentiate themselves from the competition. The unique 3D touch functionality allows the application of a UV selective varnish to perfect offset and digital prints. Digital finishing processes can increase the value of printed products [3]. For example, the perceived quality of finished packaging is 46% higher. In addition, gilding improves the attraction rate up to 2.5 times faster [4]. The longer people focus on a product, the more likely they are to choose it and attribute a higher value to it [5].

Our partner Konica Minolta believes that digital toner and inkjet printing will continue to dominate the commercial and industrial printing markets. For this reason, the Group is constantly developing equipment and solutions to meet the demands of the changing printing market.

Source :

- Page 20, Smithers « Future of Print to 2030 »

- Page 58, Smithers « Future of Print to 2030 »

- Article web - Embellishment, Transform Your Printing with Digital Varnish Technology (ennoblissement - transformez vos impressions grâce à la technologie de vernis numérique

- The foil & specialty effects association (FSEA); livre blanc : « The impact of high-visibility enhancements on shelf presence: A second Study » (Impact des améliorations à forte visibilité sur la présence en rayon : deuxième étude)

- Aradhna Krishna, Luca Cian, Nilüfer Z. Aydinoglu: « Sensory Aspects of Package Design » (Aspects sensoriels de la conception d’emballages), 2017